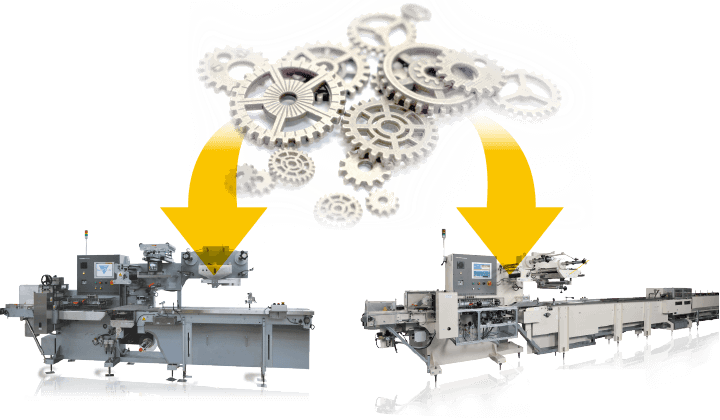

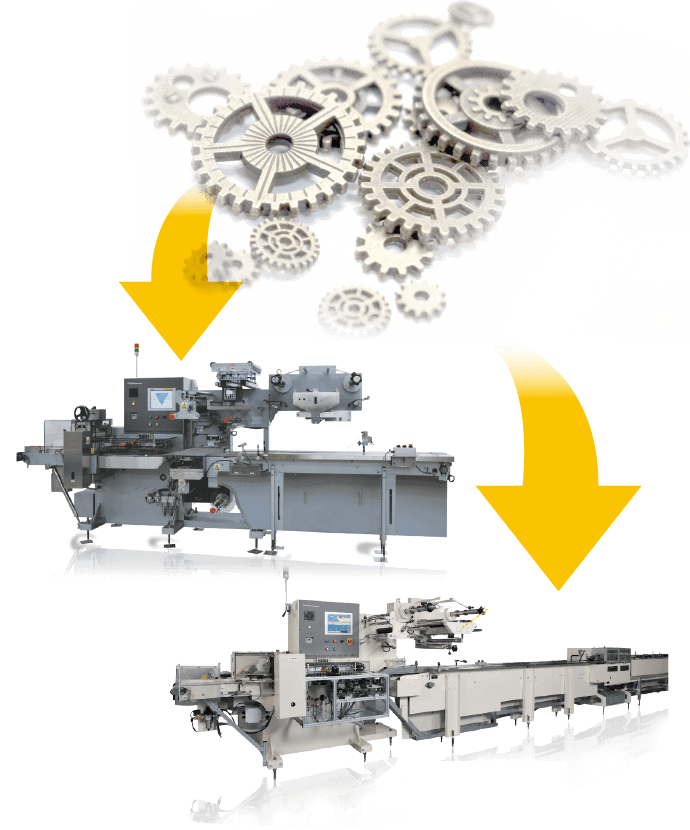

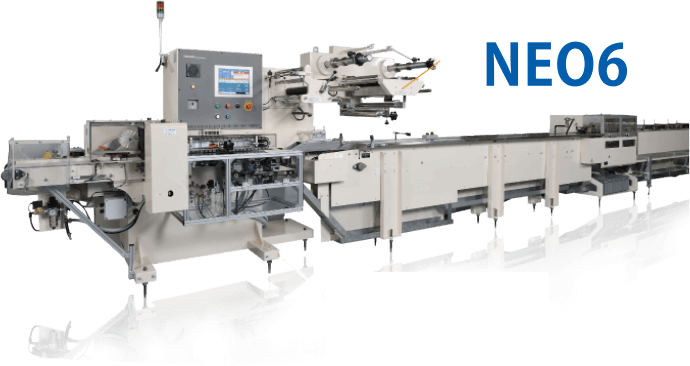

We recomend our customers to refresh TOKIWA machines for long term use. Refreshing the machines makes possible to prevent it from malfunction.

On-site machine inspection |

|

Quotation |

|

Carry out |

|---|

Quote the parts which damaged badly.

It’s possible to replace Control panel and Operation board on the machine conditions.Please contact in advance.

Due to the advance of electronical control parts, there are cases when its manufacturing is stop. For a long term use of TOKIWA machines, We provide substitute parts of machines. Please contact us for the availability.

A lot of standard parts are common whether old machines or not. We Keep doing the best to supply those parts for almost decades. And some TOKIWA machines are under operation beyond its service life.