Count on comprehensive support from even before installation to prompt emergency response

Tokiwa offers dedicated support across the entire lifecycle of your wrapping equipment, from initial installation and everyday operation to critical emergency situations. Our expert engineers provide prompt and precise assistance, ensuring the continuous and stable operation of your production lines, both domestically and internationally.

Support System

-

Before installation

At Tokiwa, we provide attentive support to ensure that you can introduce wrapping machines with peace of mind. We take into consideration the on-site environment and product specifications to propose the most suitable wrapping machine and installation plan. Our specialized staff handles everything from initial consultations to on-site inspections to resolve any concerns prior to installation. Additionally, we provide efficient operation plans and the necessary training materials with a focus on post-installation operations. We have established a system that is capable of responding to requests from both companies here in Japan and around the world. We guarantee a smooth start with clear explanations, even for first-time customers.

-

At the time of installation

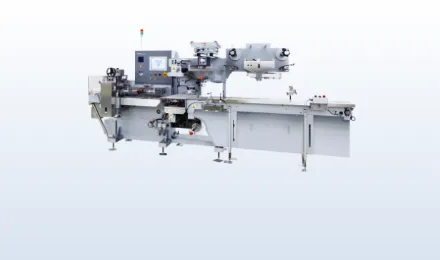

Tokiwa provides comprehensive support from equipment installation to initial setup and confirming proper operation. Our expert engineers visit your site to carefully install the wrapping machine, and they also provide clear explanations of operating methods and precautions to ensure that your staff can operate the machine smoothly. In addition, we propose the most suitable operating conditions to minimize the risk of problems. After initial operation, we conduct detailed checks to confirm stable operation. With reliable installation support, we provide peace of mind for long-term operation.

-

In case of emergency

Even in the event of an unexpected problem, we will respond quickly to minimize production line downtime. If you provide us with detailed information and photos of the issue, our specialized staff will identify the cause and respond immediately via phone or email. For simple repairs, we can provide support via phone or email, and if necessary, we will dispatch an engineer. We offer English support both domestically and internationally. We propose the best solution tailored to the nature of the issue and aim for prompt restoration. We also flexibly accommodate services outside the warranty period to ensure you have peace of mind.

After-sales Support

We provide comprehensive after-sales support to ensure that you can use our machines safely and with peace of mind for many years after installation. Through regular tune-up work and parts replacement, we help prevent breakdowns and maintain performance. By replacing control boxes and operation boxes, we allow you to benefit from the latest technology while extending the service life of your equipment. Additionally, we have established a parts supply system capable of supporting older models, enabling us to assist with machines that have exceeded their service life. We also provide advice on daily maintenance to ensure stable operation and comprehensive support.

-

Maintenance services

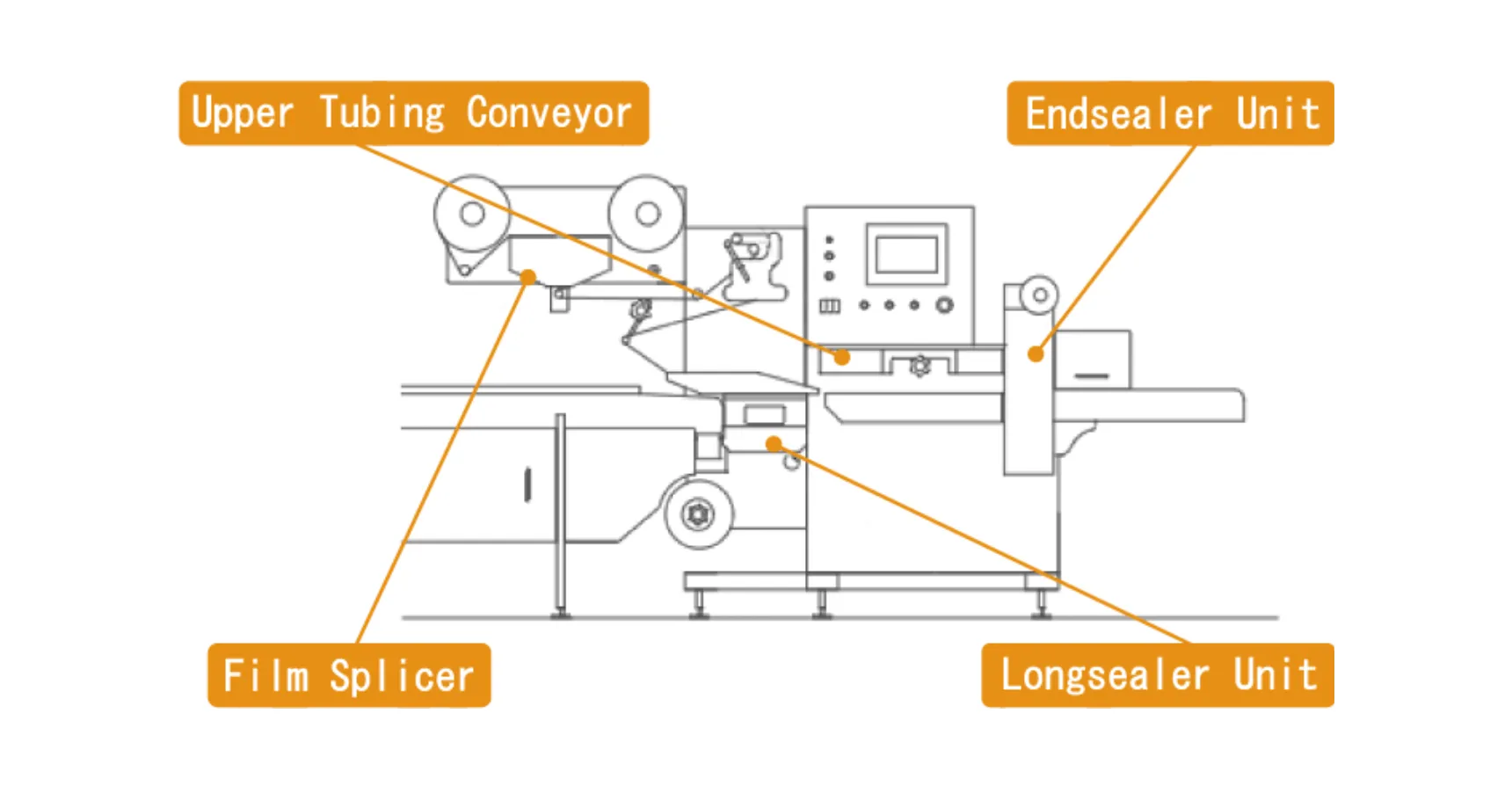

At Tokiwa, we recommend our maintenance services to ensure that our customers can use their wrapping machines for many years. Our maintenance services are performed before a machine breaks down, and regular maintenance helps prevent major breakdowns. We focus on checking parts that are subject to heavy wear, such as end sealers, long sealers, and tubing conveyors.

-

On-site survey

-

Quotation

-

Implementation

-

-

Control box and operation box replacement

We can replace the control boxes and operation boxes with the latest ones on the wrapping machines you have purchased. Electronic components that control machinery are constantly evolving, and many become obsolete, making it difficult to replace parts with the same ones. At Tokiwa, we have compatible parts available, and by replacing electrical components and operation boxes, we can help you use your machinery for a longer period of time. (Please contact us for availability.)

-

Parts supply

Tokiwa has been supplying parts for many years, as there are many standard parts common to both old and new models. The end and long sealers, which are the core components of wrapping machines, are common to most models. In addition, many machines continue operating even after exceeding their service life.

Everyday maintenance

To keep your machines in top condition for a long time, everyday maintenance (especially cleaning and oiling) is important. Please keep the six points on the right in mind and perform regular maintenance.

- When performing inspections while the machine is in operation, please be careful and pay close attention to moving parts.

- Recommended inspection cycle (1 day/8 hours, 1 week/5 days, 1 month/20 days)

- When using cleaning agents, do not apply them directly. Remove parts for cleaning or wrap them in a cloth, and wipe them dry after cleaning.

- Bolts, nuts, washers, pins, and other parts should be inspected regularly for to ensure that nothing is loose or there are any missing parts. If any abnormalities are found, please tighten or replace the parts as necessary.

- Even areas not specifically noted should be cleaned regularly.

- Do not clean painted surfaces or belt surfaces with solvents such as thinners, as this may cause peeling or corrosion.

How to deal with malfunctions

Rapid response

Tokiwa provides rapid-response support in the event of a malfunction during operation. Please work carefully, paying close attention to moving parts, and note the machine model, machine number (a 5-digit number), and details of the malfunction. Photos of where the malfunction occurred will help us identify the problem more quickly. Please provide this information by email or phone. We can also respond in English. For simple issues, we will assist in resolving them over the phone and, if necessary, dispatch an engineer to resolve the issue promptly. Please note that there will be a charge for our services if the machine is outside the warranty period.

Examples of machine problems

- ・Unusual noise

- ・Poor finish

- ・Frequent jamming in the end sealers ・Weak seals

- ・Film meandering

Examples of electrical problems

- ・Wrapping machine is not working

- ・End sealer/Long sealer temperature is not rising ・Sensor is not responding/trouble detection doesn’t work ・Error display cannot be reset

- ・Film splicer is not starting

Troubleshooting

Check the location of the problem and refer to the corresponding PDF file for the symptoms and countermeasures.