Tokiwa’s Endeavor

Changing the world with quality, trusted solutions

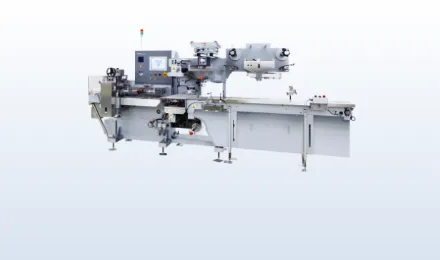

Tokiwa provides unique solutions based on the reliability of “Made in Japan” to address our customers’ challenges. Leveraging our extensive experience across a wide range of industries, from food to pharmaceuticals, we offer comprehensive support from design and manufacturing to sales and after-sales maintenance. Our wrapping machines, used in over 64 countries worldwide, combine efficiency and environmental adaptability. We are committed to continuously challenging ourselves and evolving to create the optimal solutions for our customers’ businesses.

category

A case in the dairy industry

Replacing another manufacturer’s equipment with our machines reduced defects and improved productivity.

The challenges they faced

The strength of the seals on the other manufacturer’s machine that they had been using was unsatisfactory and frequent tearing occurred, resulting in a slower wrapping speed.

Paper dust from the backing paper was caused by wrapping.

Measures taken

・Conducted seal strength tests that satisfied the customer using Tokiwa’s expertise. ・Ensured that they have a thorough understanding of the differences in machine structure compared to other companies. ・Promote measures to prevent paper dust from the backing paper based on our experience with other customers in the same industry.

Results after installation

By proposing solutions to the above issues and installing our machine, production stoppages were reduced.

Wrapping machines that had the same specifications were also supplied to other factories, which contributed to the entire group giving us a favorable evaluation.

A cosmetics-related case

Replacing another manufacturer’s equipment with our machines reduced defects and increased productivity by 200%.

Our machines are also rated as more convenient to operate than those of other companies.

The challenges they faced

The other company’s machines frequently resulted in production defects unless they wrapped at a rate of 20 packages per minute. In addition, there were many product variations, which required frequent adjustments and resulted in finished products that were inconsistent, forcing them to repackage products on a daily basis.

Measures taken

・Customers who handle cosmetics deal with a wide variety of wrapping types and shapes, so we created samples and received feedback on the finished product.

・For wrapping with particular issues, we explained why the finish is poor and proposed solutions to resolve the problem.

Results after installation

By proposing solutions to the above issues and installing our machine, they were able to increase their wrapping capacity to 40 packages per minute while maintaining stable production.

In addition, product changeover times were reduced, which improved efficiency.

Defect rates also decreased, enabling them to reduce the number of inspection personnel.

We have continued to install new machinery.

An overseas noodle manufacturing-related case

Replacing another manufacturer’s equipment with our machines improved the finish and increased the yield rate.

In addition, we have increased production efficiency and gained recognition for Tokiwa Kogyo’s technology from overseas customers.

The challenges they faced

Low operational stability causes defective products to enter the market, resulting in customer complaints.

Measures taken

・We proposed automating product supply methods with the aim of improving production efficiency.

・We introduced our unique expertise and extensive track record to ensure stable operation.

We took the initiative in proposing not only wrapping machines but also coordination with other companies’ wrapping-related equipment.

・We asked them to visit Japan and showed them the actual machines and presented finished samples.

We discussed current issues and made a change to the most suitable sealing method.

Results after installation

By proposing solutions to the above issues and installing our machine, the defect rate has decreased.

By automating the supply method, they have achieved stable production and successfully reduced the number of inspection personnel.

In addition, by changing the seal type, the width and pitch of the wrapping film have been reduced compared to before, resulting in a reduction in film costs.

They switched to Tokiwa Kogyo from another wrapping machine manufacturer they had been working with, and we are still contributing to the planning of new wrapping processes.

A sake pack-related case

Replacing equipment from another manufacturer to our machines improved the finish and increased the yield rate.

The challenges they faced

There were market complaints due to poor sealing with other companies’ wrapping machines, products getting damaged inside the wrapping machines, and poor finish caused by water droplets adhering to the sake pack during the manufacturing process.The customer wanted to improve the appearance compared to conventional wrapping.

Measures taken

・We proposed a supply method to reduce the damage to products when transporting heavy sake packs.・We took the initiative in proposing collaboration with other companies’ equipment to efficiently remove the water droplets.

・We introduced our unique expertise and extensive track record to ensure stable operation.

・We discussed current issues and made a change to the most suitable sealing method.

Results after installation

By proposing solutions to the above issues and installing our machine, the defect rate has decreased.Stable production has been achieved, enabling a reduction in inspection personnel and leading to labor savings. In addition, changes to the seal configuration have shortened the width and pitch of the wrapping film compared to the previous models, reducing film costs and eliminating the need for film disposal. Rust issues that had been a long-standing problem with other manufacturers’ machines have also been resolved, improving production efficiency.

An aerosol-related case

Replacing the existing Tokiwa wrapping machine resulted in a 5% improvement in yield.

The challenges they faced

The customer had been using a wrapping machine delivered over 30 years ago, but was concerned about the discontinuation of electrical components. Due to long-term use, there were many parts that had worn out and required adjustment, resulting in a decrease in stable operating time and an increase in the rate of defective products.

Measures taken

・We promoted the advantages of replacing the wrapping machine, such as the improved durability of the electrical components and other improvements that have made to the existing machine. We strived to resolve any concerns that the customer had.

Results after installation

By proposing solutions to the above issues and installing our machine, the defect rate has decreased significantly.

Short downtimes also decreased, and while mold change adjustments used to take a long time with the previous wrapping machine, that time has been shortened, improving efficiency.

Parts consumption also decreased, reducing annual parts costs, and the replacement led to positive feedback from the customer.