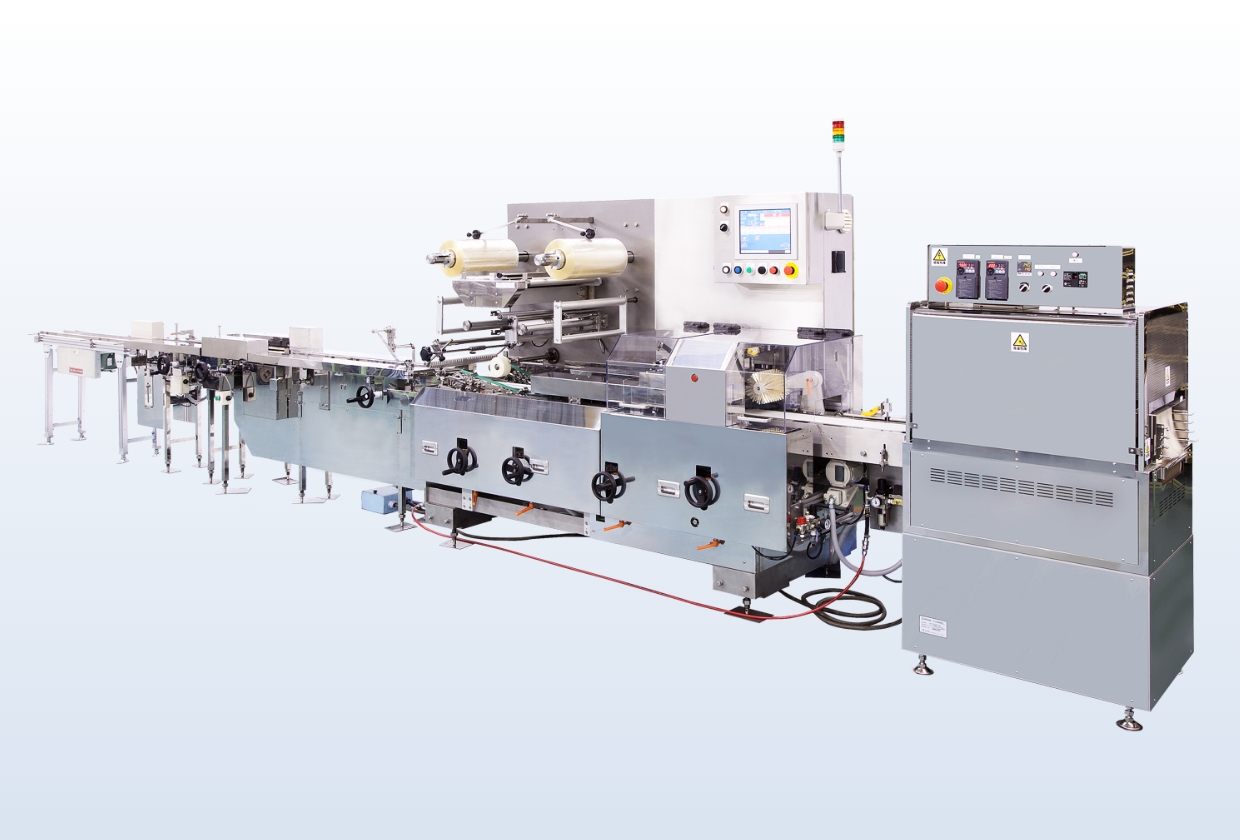

After receiving mainly frozen products and chilled foods on an infeed conveyor, stretch wrapping is performed.

Target Products

- frozen noodles

- Other frozen foods

feature

-

feature

This device receives products fed from the previous process on a roller type pool conveyor, divides them into individual units using an auto feeder, and then stretch wraps them after receiving them on an infeed conveyor.

-

feature

The main body and major parts are made of stainless steel or aluminum to prevent rust, and can be cleaned with water for excellent sanitary performance.

-

feature

Safety and operability during setup have been improved by including a switch to stop the end sealer independently as standard equipment.

Examples of Uses

Frozen foods

Frozen products are highly susceptible to changes in temperature and the surrounding conditions during wrapping, which can significantly affect their smoothness and other characteristics. For this reason, this model is specially designed with specifications tailored specifically for frozen products.

Product Specifications

- Packaging Capacity

- MAX. 120 packs/minute (depending on product and wrapping materials)

- Main Motor

- 200V 750W (AC servo): 3 units

- Power consumption

- 3-phase 200V 12.0kW

Selection Options

Box Motion

Unlike conventional rotary sealing methods, the sealer moves around the box, allowing for longer sealing pressure time. This results in significantly improved sealing performance compared to rotary sealing methods. This method is widely used for food packaging that requires inert filling or oxygen absorber sealing.

Hermetic Sealer (End Sealer)

Compared to conventional box motion-type end sealers, rotary-type hermetic end sealers enable high-speed sealing. Compared to conventional rotary sealers, longer sealing times improve sealing performance, enabling a maximum of 300 packs/min.

Stretch Conveyor (Tubing Conveyor, Discharge Conveyor)

The conveyor slide type is adopted for conveyors before and after the rotary sealer. This ensures seal strength while reducing the load collapse of products that are prone to collapsing or are in multi-pack wrapping.

Auto Film Splicer

As wrapping continues, the film will eventually run out. Normally, wrapping is temporarily stopped at this point, a new roll of film is loaded, and the process is restarted. The film splicer is a device that automatically attaches the end of the used film to the beginning of the new film by preloading a new roll of film into a separate film holder. By adopting a film splicer, there will be no need to temporarily interrupt packaging for film replacement, thereby improving production efficiency. Depending on the type of film, there are two options: the tape seal type, which connects using double-sided tape, and the heat seal type, which obviates the cumbersome application of tape and instead uses heat sealing for single-film or double-sided adhesive films.

Printer

It prints the date of manufacture and expiration date according to the intended use. An inkjet inspection device can also be installed, and depending on the type of printer, it can check for blurred characters and printing errors.

Various Auto Feeders

We offer a wide range of auto feeders such as BDA, star wheels, and screws according to the products to be wrapped.

Film Center Adjustment Device

It automatically detects film skew and stabilizes long sealing. Combining it with a splicer enables even higher productivity.