Servo motor drive with end-sealer height adjustment allows for a wide range of applications.

Target Products

- aerosol

- bottled medicine

- Cup Soup/Cup Noodles

- daily necessities

- dairy products

- paper carton beverage

- Various containers

feature

-

feature

The NEO series is the culmination of soft technology. Not only does it offer outstanding performance, but it is also extremely user-friendly. Thanks to its microcomputer control, it can be operated easily without an operating manual.

-

feature

Wrapping with printed shrink film can be done and costs reduced by using printed film regardless of the product to be wrapped.

-

feature

Safety and operability during setup have been improved by including a switch to stop the end sealer independently as standard equipment.

Examples of Uses

Aerosol can

We wrap various products such as hair styling products and insecticides. Depending on the type, there are nozzles, triggers, etc. Aerosol cans come in a variety of types. In addition, double spray can wrapping is also commonly seen in the market.

Cup noodles

We wrap various products such as vertical cups, bowls, square containers, and more. Customers who produce ramen noodles often require high-speed processing. For vertical cup products, we are sometimes asked to install a device that turns the upright products horizontal during the production process for wrapping.

Dairy products

We also package products such as yogurt and dessert cups with a backing sheet placed under the product. We can also supply a device for feeding the backing sheet together with the wrapping machine.

AUTO FEEDERS

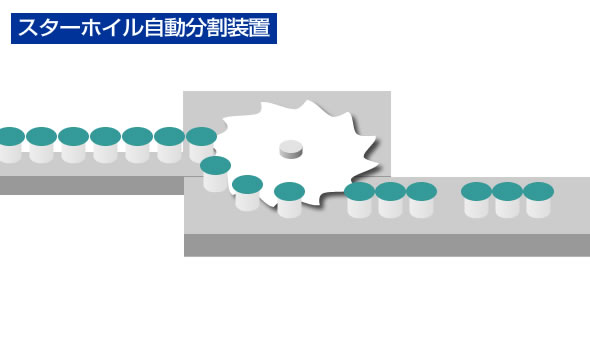

Starwheel Auto Feeder(Single)

This device automatically feeds a specified quantity of cup products (such as yogurt) in round containers. By incorporating a clutch into the drive system, the quantity can be divided into different amounts. Additionally, by replacing the star wheel, the device can also handle products with different diameters.

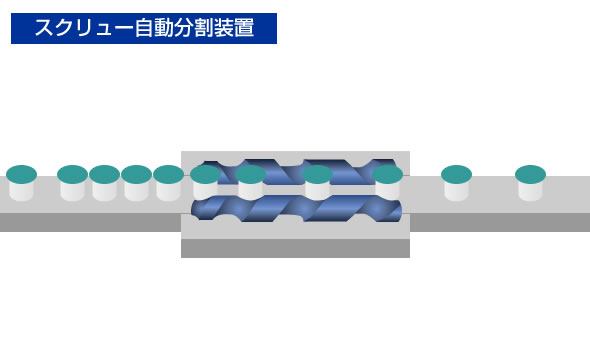

Screw Type Auto Feeder

This device automatically feeds specified quantities of round containers and other items, starting from a single unit. By replacing the screw, it can also handle products with different diameters. Additionally, depending on the product, the product can be rotated 90 degrees forward. For products requiring high-speed processing with relatively small diameters, we configure the system using a Multi Starts Tread Screw.

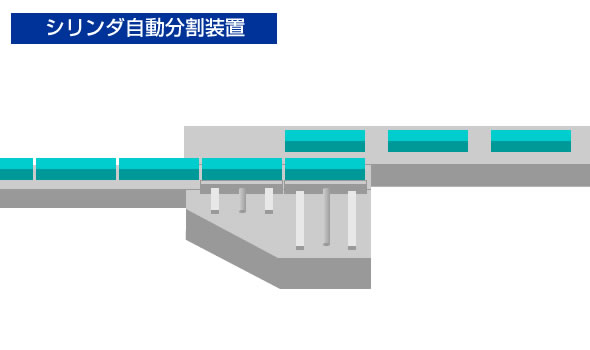

Cylinder Type Auto Feeder

This device automatically feeds specified quantities, such as cartons, starting from a single unit. *Wrapping capacity is up to 20 packs per minute. A timing cam is used to insert products between the infeed conveyor attachments using air cylinders.

Bar Type Auto Feeder

This device automatically feeds cartons and other items one at a time. The bar pitch cannot be changed, so this device cannot be used for products that are different sizes in the machine direction.

BDA2-M1B1 Auto Feeder

This device automatically feeds cartons and other items one at a time. Products fed onto the pool conveyor are divided into specified quantities by the BDA2-M1B1 automatic dividing feeder unit and then fed onto the infeed conveyor. It has a position alignment tracking function that inserts products between the attachments of the infeed conveyor using the upper and lower pinch belts.

BDA2-M1B2 Auto Feeder

This device automatically feeds cartons and other items one at a time. Products fed onto the pool conveyor are divided into specified quantities by the BDA2-M1B2 automatic dividing feeder unit and then fed onto the infeed conveyor. The first belt is set to the speed of the product feed length, and the second belt is set to the chain pitch speed of the infeed conveyor. It has a position alignment tracking function that inserts products between the attachments of the infeed conveyor.

BDA2 - Tilting Device

This device is used to change the feeding posture for automatic division and supply. This device is used to rotate the product by 90 degrees from itsupright position as it is conveyed from the upstream process.

Product Specifications

- Packaging Capacity

- MAX. 300 packs/minute (depending on product and wrapping materials)

- Main Motor

- 200V 750W (AC servo): 3 units

- Power consumption

- 3-phase 200V 5.5kW (separate power supply required for shrink tunnel)

- Film width

- 580 mm

- Cutting dimensions

- 130-600 mm

Selection Options

Box Motion

Unlike conventional rotary sealing methods, the sealer moves around the box, allowing for longer sealing pressure time. This results in significantly improved sealing performance compared to rotary sealing methods. This method is widely used for food packaging that requires inert filling or oxygen absorber sealing.

Hermetic Sealer (End Sealer)

Compared to conventional box motion-type end sealers, rotary-type hermetic end sealers enable high-speed sealing. Compared to conventional rotary sealers, longer sealing times improve sealing performance, enabling a maximum of 300 packs/min.

Stretch Conveyor (Tubing Conveyor, Discharge Conveyor)

The conveyor slide type is adopted for conveyors before and after the rotary sealer. This ensures seal strength while reducing the load collapse of products that are prone to collapsing or are in multi-pack wrapping.

Electrostatic Long Sealer

Compared to fusion seals, it reduces the amount of film used and the number of consumable parts in the machine. Compared to wrap seals, the seal line is not visible, resulting in a beautiful finish on the sealed surface.

Minimum Pin Hole Device

For customers using printing film, this device makes countless small pin holes that do not interfere with the design.

One-touch Scrap Winding Device

This device winds scrap film without the need for a paper tube. When the scrap film accumulates, it can be removed with a single touch.

Auto Film Splicer

As wrapping continues, the film will eventually run out. Normally, wrapping is temporarily stopped at this point, a new roll of film is loaded, and the process is restarted. The film splicer is a device that automatically attaches the end of the used film to the beginning of the new film by preloading a new roll of film into a separate film holder. By adopting a film splicer, there will be no need to temporarily interrupt packaging for film replacement, thereby improving production efficiency. Depending on the type of film, there are two options: the tape seal type, which connects using double-sided tape, and the heat seal type, which obviates the cumbersome application of tape and instead uses heat sealing for single-film or double-sided adhesive films.