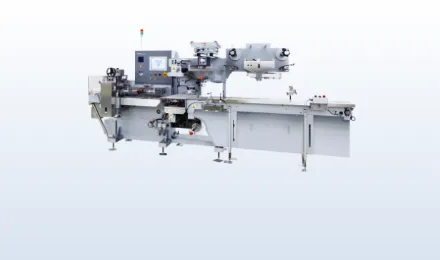

The film is fed from below, allowing products delivered from the infeed conveyor to be placed directly onto the film. This makes it ideal for packaging multiple items such as drip coffee or five-pack instant noodle bundles.

Target Products

- drip coffee

feature

-

feature

The film is fed from below, and products sent from the infeed conveyor are fed onto the film, making it ideal for multi-pack wrapping.

-

feature

By making folding lines on the film and adding headers and footers, a finish similar to that of bag-form wrapping can be achieved.

-

feature

The electrical components have been completely redesigned to enable remote program changes and alarm history output.

-

feature

A servo motor has been added to the film drive section to improve wrapping accuracy with printed film.

Examples of Uses

Drip coffee

Drip coffee can be gathered for multi-pack wrapping in the same way as bagged products.

Product Specifications

- Power consumption

- 3-phase 200V 6.0kW

Selection Options

Adjustable Forming Box

The height and width can easily be adjusted, eliminating the need to change the bagging machine when switching product types, which saves time and allows for a wide variety of products to be wrapped.

Printer

It prints the date of manufacture and expiration date according to the intended use. An inkjet inspection device can also be installed, and depending on the type of printer, it can check for blurred characters and printing errors.

Film Center Adjustment Device

It automatically detects film skew and stabilizes long sealing. Combining it with a splicer enables even higher productivity.

Grouping Machine

Products that flow in randomly are divided into specified quantities, gathered, and supplied to the wrapping machine.

Auto Film Splicer

As wrapping continues, the film will eventually run out. Normally, wrapping is temporarily stopped at this point, a new roll of film is loaded, and the process is restarted. The film splicer is a device that automatically attaches the end of the used film to the beginning of the new film by preloading a new roll of film into a separate film holder. By adopting a film splicer, there will be no need to temporarily interrupt packaging for film replacement, thereby improving production efficiency. Depending on the type of film, there are two options: the tape seal type, which connects using double-sided tape, and the heat seal type, which obviates the cumbersome application of tape and instead uses heat sealing for single-film or double-sided adhesive films.

Various Knives

Various knives are available to select the cut for the opening, which makes the product easier to open.

Gusset Device

By incorporating a gusset into the film, the appearance of the wrapping is improved and the shape becomes easier to pack into boxes.

Film Folding Device

By making folding lines on the film, it can be formed into a neat box shape when bagged.

U-cut Device

Easy switching between different types of degassing holes thanks to independent motor control.