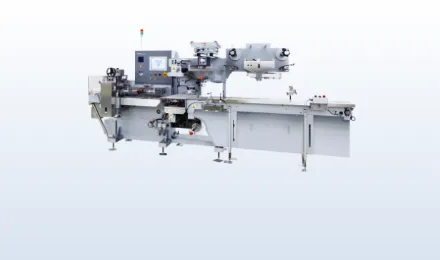

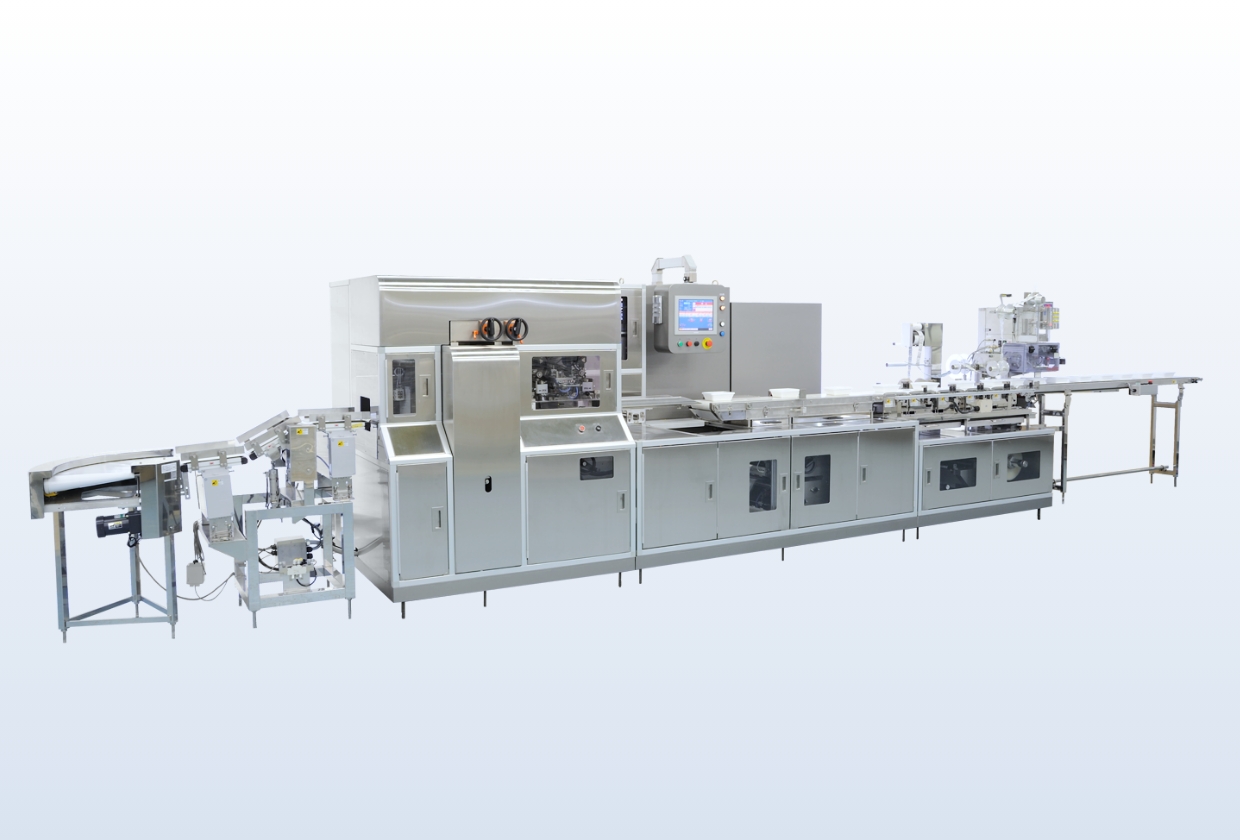

Products fed manually onto the conveyor are received by a multistage belt-divided auto feeder, deoxidizers are automatically added, and the products are divided into individual units before being fed into the wrapping machine. The products are then pillow-wrapped using a specified film.

Target Products

- confectionery

feature

-

feature

After placing soft products in the designated position so that they will not change shape as the result of external pressure, we automatically divide the products so that they do not come into contact with each other, transport them, and then wrap them.

-

feature

Even for thick films with high barrier properties, folding lines can be created to achieve a finish similar to that of bag-form wrapping.

-

feature

By customizing the film transport system, gussets can neatly be incorporated without being affected by the shape of the product. For example, soft products (such as Baumkuchen) can also neatly be wrapped.

-

feature

Adopting a belt-divided auto feeder (non-attachment) enables automatic feeding and wrapping even for products without trays, leading to reduced running costs and waste.

Examples of Uses

Confectionery

It is also used for Western-style confectionery, where sealing is important to maintain product quality.

AUTO FEEDERS

Box Motion

Unlike conventional rotary sealing methods, the sealer moves around the box, allowing for longer sealing pressure time. This results in significantly improved sealing performance compared to rotary sealing methods. This method is widely used for food packaging that requires inert filling or oxygen absorber sealing.

Hermetic Sealer (End Sealer)

Compared to conventional box motion-type end sealers, rotary-type hermetic end sealers enable high-speed sealing. Compared to conventional rotary sealers, longer sealing times improve sealing performance, enabling a maximum of 300 packs/min.

Stretch Conveyor (Tubing Conveyor, Discharge Conveyor)

The conveyor slide type is adopted for conveyors before and after the rotary sealer. This ensures seal strength while reducing the load collapse of products that are prone to collapsing or are in multi-pack wrapping.

Auto Film Splicer

As wrapping continues, the film will eventually run out. Normally, wrapping is temporarily stopped at this point, a new roll of film is loaded, and the process is restarted. The film splicer is a device that automatically attaches the end of the used film to the beginning of the new film by preloading a new roll of film into a separate film holder. By adopting a film splicer, there will be no need to temporarily interrupt packaging for film replacement, thereby improving production efficiency. Depending on the type of film, there are two options: the tape seal type, which connects using double-sided tape, and the heat seal type, which obviates the cumbersome application of tape and instead uses heat sealing for single-film or double-sided adhesive films.

Product Specifications

- Packaging Capacity

- MAX. 40 packs/minute (depending on product and wrapping materials)

- Main motor

- AC servo 750W/AC servo 400W (2 units)/AC servo 100W

- Power consumption

- 3-phase 200V 8.5kW

- Film sensitivity

- 590 mm

Selection Options

Non-Attachment Conveyor

Suitable for transporting soft products, etc., as the product is transported by a belt with no attachments being used.

Auto Film Splicer

As wrapping continues, the film will eventually run out. Normally, wrapping is temporarily stopped at this point, a new roll of film is loaded, and the process is restarted. The film splicer is a device that automatically attaches the end of the used film to the beginning of the new film by preloading a new roll of film into a separate film holder. By adopting a film splicer, there will be no need to temporarily interrupt packaging for film replacement, thereby improving production efficiency. Depending on the type of film, there are two options: the tape seal type, which connects using double-sided tape, and the heat seal type, which obviates the cumbersome application of tape and instead uses heat sealing for single-film or double-sided adhesive films.

Adjustable Forming Box

The height and width can easily be adjusted, eliminating the need to change the bagging machine when switching product types, which saves time and allows for a wide variety of products to be wrapped.

Printer

It prints the date of manufacture and expiration date according to the intended use. An inkjet inspection device can also be installed, and depending on the type of printer, it can check for blurred characters and printing errors.

Various Knives

Various knives are available to select the cut for the opening, which makes the product easier to open.

Film Center Adjustment Device

It automatically detects film skew and stabilizes long sealing. Combining it with a splicer enables even higher productivity.

Film Folding Device

By making folding lines on the film, it can be formed into a neat box shape when bagged.

Ionizer

It removes static electricity from the film and products, preventing them from sticking to the film and getting caught in the sealer.

Gusset Device

By incorporating a gusset into the film, the appearance of the wrapping is improved and the shape becomes easier to pack into boxes.