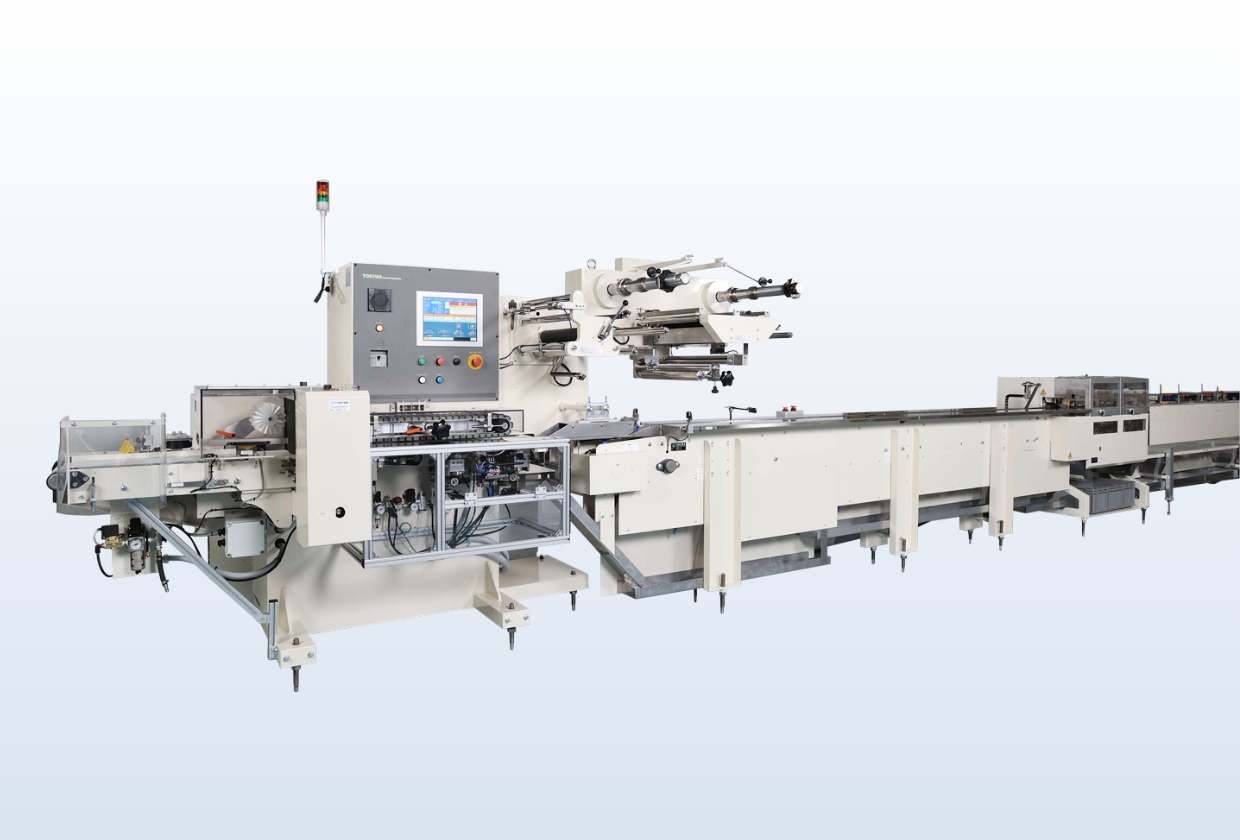

This machine was developed for bag noodles and can quickly wrap with relatively thick, non-shrink film.

Target Products

- confectionery

- frozen noodles

- instant noodles

feature

-

feature

This machine was developed for bag noodles and it can wrap quickly with relatively thick film.

-

feature

By adopting a new seal mechanism for the long sealer, it can now run even with empty bags, enabling stable wrapping without being affected by product shape. In addition, there will be no need to feed the film by hand during setup, which improves safety.

-

feature

Safety and operability during setup have been improved by including a switch to stop the end sealer independently as standard equipment.

Examples of Uses

Bag noodles

Many bag noodles, both produced domestically and overseas, come with small bags of soup powder and seasoning. Customers require the seasoning to be wrapped without any leakage or clumping during the wrapping process, rather than simply wrapping the noodles alone.

AUTO FEEDERS

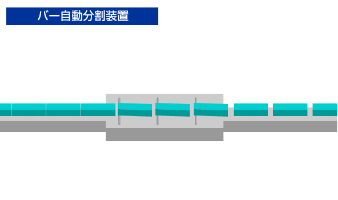

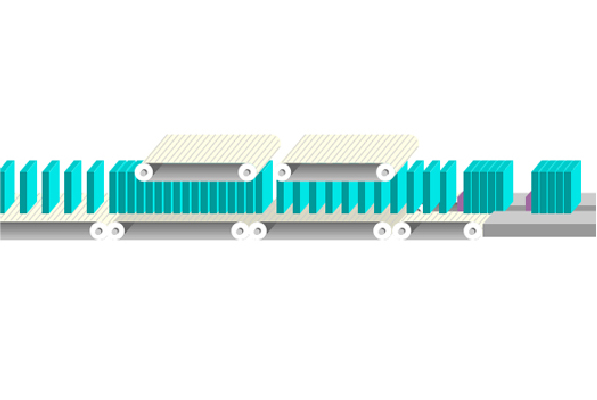

Bar Type Auto Feeder

This device automatically feeds cartons and other items one at a time. Products fed onto the pool conveyor are divided into individual pieces by the bar automatic dividing feeder unit and then fed onto the infeed conveyor. The bar pitch cannot be changed, so this device cannot be used for products that are different sizes in the machine direction.

BDA2-SE Auto Feeder

This device automatically feeds cartons and other items one at a time. Products fed onto the pool conveyor are divided into specified quantities by the BDA2-SE automatic dividing feeder unit and then fed onto the infeed conveyor. It has a position alignment tracking function that inserts products between the attachments of the infeed conveyor using the upper and lower pinch belts.

BDA2-M1B1 Auto Feeder

This device automatically feeds cartons and other items one at a time. Products fed onto the pool conveyor are divided into specified quantities by the BDA2-M1B1 automatic dividing feeder unit and then fed onto the infeed conveyor. It has a position alignment tracking function that inserts products between the attachments of the infeed conveyor using the upper and lower pinch belts.

Product Specifications

- Packaging Capacity

- MAX. 300 packs/minute (depending on product and wrapping materials)

- Main motor

- 200V 750W (AC servo): 3 units, long sealer: 200V 200W (AC servo)

- Power consumption

- 3-phase 200V 4.5kW

- Film sensitivity

- 450 mm

- Cut size

- 80-380 mm

Selection Options

Box Motion

Unlike conventional rotary sealing methods, the sealer moves around the box, allowing for longer sealing pressure time. This results in significantly improved sealing performance compared to rotary sealing methods. This method is widely used for food packaging that requires inert filling or oxygen absorber sealing.

Hermetic Sealer (End Sealer)

Compared to conventional box motion-type end sealers, rotary-type hermetic end sealers enable high-speed sealing. Compared to conventional rotary sealers, longer sealing times improve sealing performance, enabling a maximum of 300 packs/min.

Stretch Conveyor (Tubing Conveyor, Discharge Conveyor)

The conveyor slide type is adopted for conveyors before and after the rotary sealer. This ensures seal strength while reducing the load collapse of products that are prone to collapsing or are in multi-pack wrapping.

Auto Film Splicer

As wrapping continues, the film will eventually run out. Normally, wrapping is temporarily stopped at this point, a new roll of film is loaded, and the process is restarted. The film splicer is a device that automatically attaches the end of the used film to the beginning of the new film by preloading a new roll of film into a separate film holder. By adopting a film splicer, there will be no need to temporarily interrupt packaging for film replacement, thereby improving production efficiency. Depending on the type of film, there are two options: the tape seal type, which connects using double-sided tape, and the heat seal type, which obviates the cumbersome application of tape and instead uses heat sealing for single-film or double-sided adhesive films.